IPI’s CITT is a live-well deployable, high expansion, multi-set inflatable testing packer. The CITT allows operators to pass through wellbore restrictions and set inside larger IDs, for testing the zone above the packer element. Conveyed by jointed or coiled tubing, the CITT takes advantage of IPI’s robust and durable element design technology which provides the operator with best-in-class element retraction post-testing, lowering the chances of being hung up on wellbore restrictions or completions equipment on the way out of the hole. In reservoir stimulation operations, the CITT provides a simple and quick method of temporarily isolating specific zones within the well which allows the operator to place more accurate and precise treatment/stimulations.

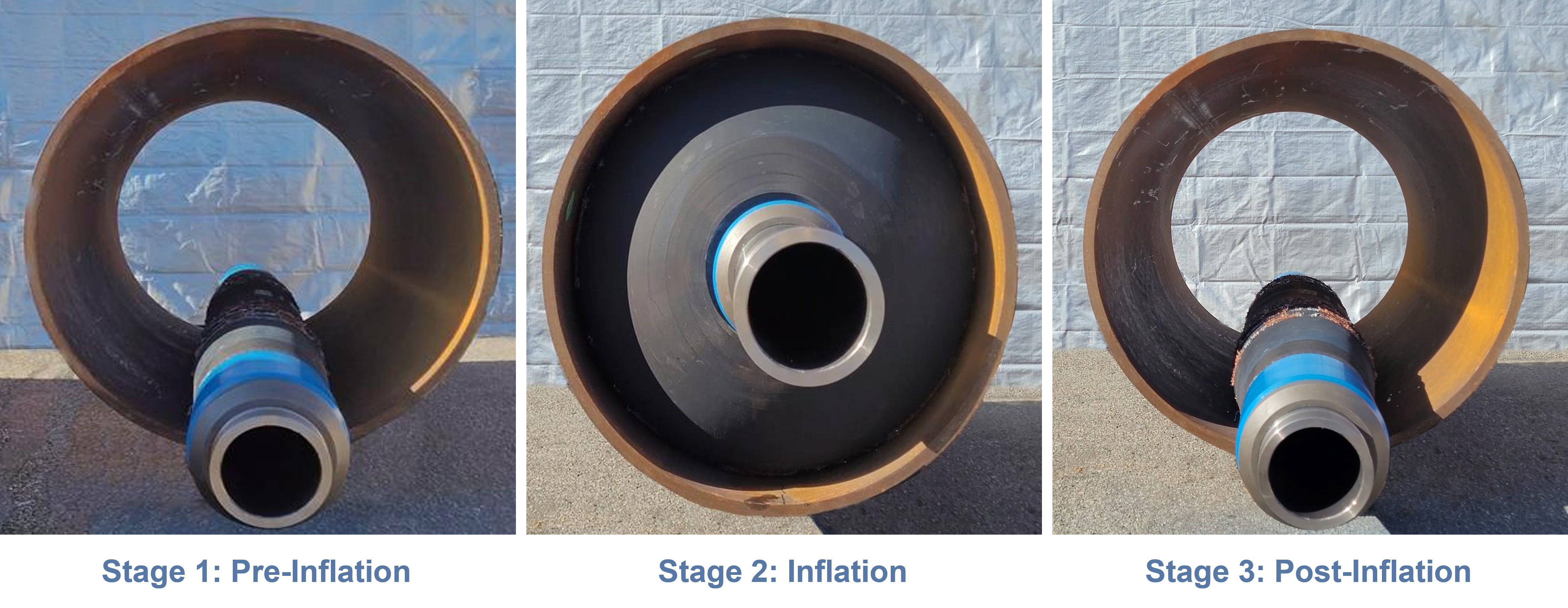

IPI’s inflatable element is a highly versatile hydro-mechanical sealing device, engineered for deployment into the wellbore on a wide range of tool chassis. Unique in its design, the IPI element can be set in internal diameters (ID) up to 300% larger than its run-in outside diameter (OD)* – and where required, can also be released and retrieved. This dual-direction sealing capability ensures true wellbore isolation, even in the most challenging environments.

Proven in thousands of operations worldwide, the IPI inflatable element is recognized as the industry’s most robust and reliable inflatable sealing solution, offering best-in-class recoverability. It excels in both cased and open hole applications, and performs effectively in irregular wellbore conditions including ovality, scale, perforations, and non-standard geometries – delivering ultimate operational flexibility from a single solution.

*Performance capabilities vary depending on specific element design and hole conditions.

Yes, unlike mechanical packers, inflatable packers don’t have any limitations on deviation at the setting depth.

Inflatable Packers are set by pumping fluid in them. You can use Drill pipe, Coiled Tubing or any other workstring to run them in the hole and inflate them.

Stuart recently joined IPI as the Director of Oil and Gas, bringing with him 15 years of diverse experience in the industry, with a strong focus on inflatable packers. His extensive background encompasses a variety of roles, including field engineering, operations management, sales, and business development. This breadth of expertise, coupled with his international experience in markets across North America, Europe, Australia, and the Middle East, positions Stuart to effectively lead and expand IPI’s oil and gas operations on a global scale. Stuart holds a Master’s degree in Mechanical Engineering from the University of Aberdeen and a Master’s degree in Finance from City University of London. His robust technical foundation and financial acumen uniquely empower him to drive strategic initiatives and foster growth within the company.

Made Differently, Perform Better

Discover why we’re the market leader for

Inflatable Packers across a variety of industries.